The trucks we develop are unrivalled in their effectiveness for projects involving substantial distances. The trucks provided by BAS Mining Trucks offer the perfect solution for distances ranging from as little as 1 km to as far as 250 km between loading zone and dump zone. The trucks offered by BAS Mining Trucks offer low purchasing, maintenance and fuel costs.

This reliable transmission makes the truck very special. The 6-speed transmission is provided with a torque converter that more than doubles the torque in first two and reverse gear and delivers continuous traction, even when changing gear, making it ideal for working in extreme conditions.

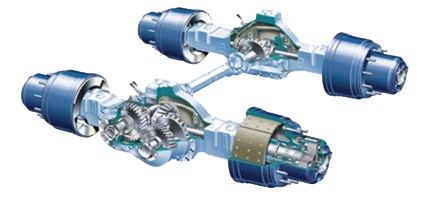

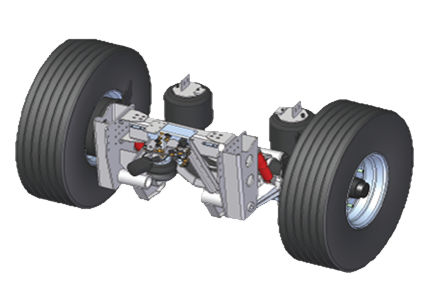

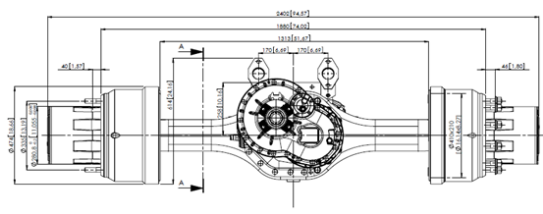

RT3312 is a tandem axle with hub reduction. The maximum axle loading is 40 tonnes at a speed of 60 km/h. It is designed for heavy, demanding haulage. The two-axle drive means that the tractive effort can be transferred to the ground without wheel slip, giving excellent grip and very low tyre wear.

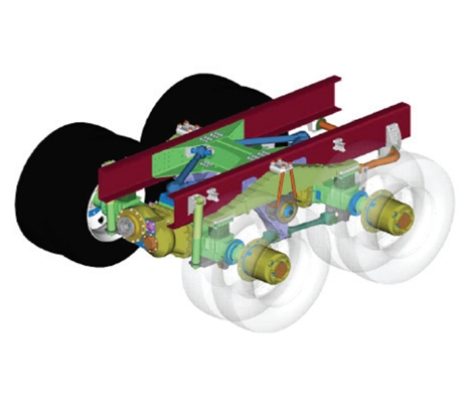

The RADD-TR2 is a lubrication free, robustly dimensioned leaf spring suspended bogie for tandem drive rear axles. It is available with a 9- or 11-leaf conventional multi-leaf spring, which both are particularly designed for Very Rough conditions (Road condition according to Global Truck Application).

RSAP2 is a reinforced bogie to better withstand high loads under tough conditions.

We mount an extra stabilizer between 3th and 4th axle. This creates more stability for the complete vehicle and therefore enhances safety.

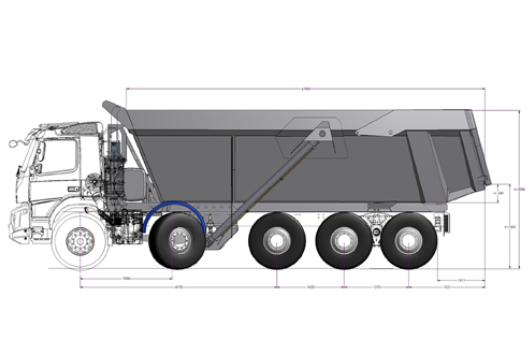

Due to the placing of the additional 14-tonnes axle, the 10×4 tipper and pusher can handle more payload and therefore gains a broader scope. The axle is liftable & steered.

Due to the placing of the additional 20-tonnes axle, the pusher with single mounted tyres can handle more payload and therefore gains a broader scope. The axle is steered & driven, which increases traction on rough terrain.

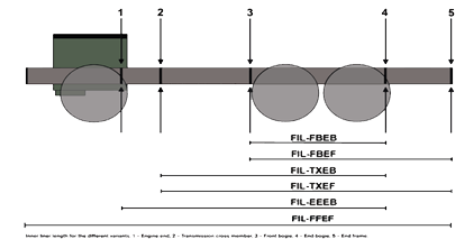

For vehicles dealing with high frame stress, it is recommended to add reinforcements to the frame over the most exposed areas. The frame full inner liner is a 5 mm thick reinforcement profile, made from high-strength steel, that is applied from the front to the end of the frame. It provides rigidity and strength to entire truck frame making the trucks ideally suited for heavy duty off road applications.

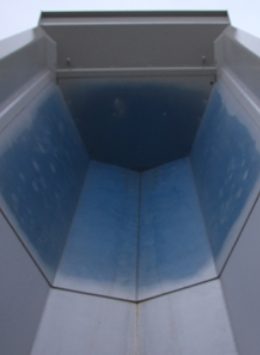

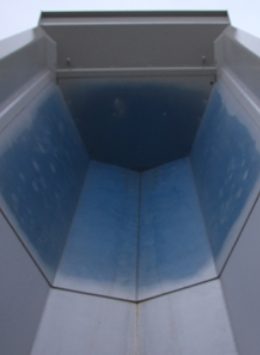

The two cylinders have double action. The tipper is squeezed upwards and is then pulled back down again. That saves a lot of dump time. The tipper has a special shape, so it already empties during dumping, thereby emptying as quickly as possible. Tiptime up 28 seconds, down 19 seconds.

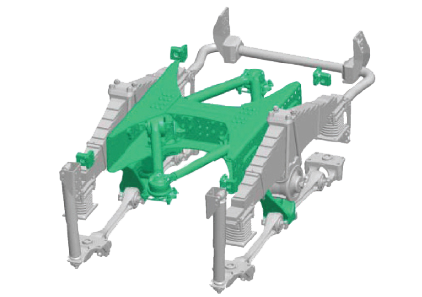

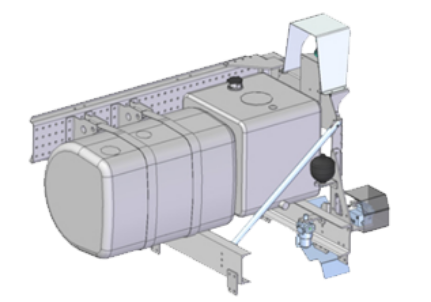

The component frame has 3 functions: (1) protect the vehicle fuel tank, battery box, air tanks and hydraulic tank for damages (2) mounting bracket for gearbox cooler, steering gear cooler, tipper hydraulics and central lubrication system (3)optimizes the tipper mounting in respect to the weight distribution and creating space for the tilting cylinders

BAS Mining Trucks offers the Truck Payload Measuring System on all models. This system allows the driver to see the exact total truck weight and payload. The Trucks Monitoring System and Truck Payload Measuring System can be combined to offer a continuous measurement of production in tonnes per hour. It will then also tell the fleet manager when the trucks are overloaded or under loaded and the loader operators can be advised.

In addition to the payloads, the system can also be equipped with an indicator system on the side and rear of the truck allowing the loader operator to know if the truck is loaded to its full capacity or if an additional bucket can be loaded. This results in higher efficiency and lower cost per tonne.

As a stand-alone option, the system will store all loads. At the end of each shift the loads can be downloaded allowing for a correct production calculation.

Knowing the truck payload not only has an advantage from a production point of view. But it also results in a lower cost per tonne because corrective actions can be taken when truck payloads are too high.

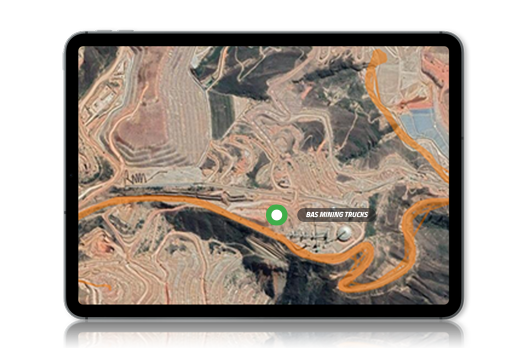

BAS Mining trucks offers the BAS Fleet Connect. This system allows for continuous monitoring of all vital truck data such as engine parameters, location, fuel consumption, driver and more. In addition, the system is coupled to other systems that BAS Mining Trucks offers such as Truck Payload Measuring System and a Tyre Pressure Monitoring System.

The BAS Fleet Connect offers an opportunity to reduce cost per tonne. Failures can be detected before they actually occur and preventive measures can be taken to keep the mechanical availability at a high level.

By applying Hardox 500 steel wear plates, even the hardest rock results in significantly less wear during the many dumping operations.

The Volvo FMX 10x4 tipper has been successfully deployed throughout the world. Tipper bodies with a special anti-adherent coating to counteract the ‘stickiness’ of bauxite. This and other innovations are guaranteed to simplify your business operations and greatly increase efficiency.